Teflon Fabric

- Model

- Teflon Fabric

Review

Description

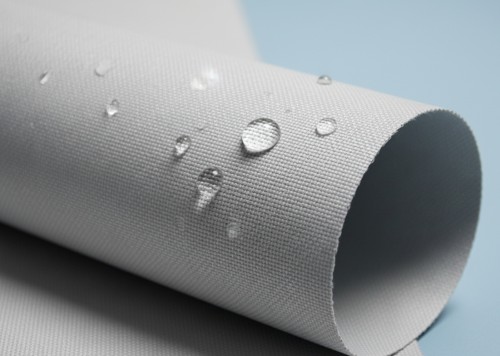

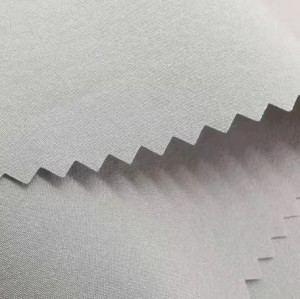

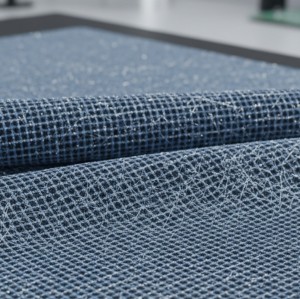

The Ultimate High-Performance Release MaterialOur PTFE Coated Fiberglass Fabric (Polytetrafluoroethylene, commonly known by the brand name Teflon™) is a highly durable composite material designed for extreme industrial environments.1 It combines the mechanical strength and dimensional stability of a woven fiberglass cloth with the superior chemical and thermal resistance of a smooth, non-stick PTFE coating.2This material is the ideal choice for applications demanding exceptional release properties, continuous high-temperature service, and inertness to corrosive chemicals.Key Features and BenefitsExceptional Non-Stick Surface: The PTFE coating delivers an incredibly low coefficient of friction, ensuring rapid and easy release of sticky materials, resins, glues, and food products without residue buildup.3High Temperature Resistance: Rated for continuous use up to 4$500^\circ\text{F}$ (5$260^\circ\text{C}$), making it perfect for industrial ovens, heat-sealing, and curing processes.6Chemical Inertness: Unaffected by most acids, alkalis, solvents, and corrosive agents, offering long-term reliability in harsh chemical processing and gasketing environments.7Superior Durability: The fiberglass base provides high tensile strength and dimensional stability, resisting tears, stretching, and distortion even under mechanical stress.8Waterproof and Moisture Resistant: The non-porous coating creates a hermetic seal (as seen in the image), protecting the substrate and preventing water or oil penetration.9Excellent Electrical Insulation: Provides high dielectric strength, suitable for electrical insulating barriers and phase separators.Industry Use Case

Food Processing Non-stick baking/drying belts, reusable pan liners (Food Grade options available), release sheets for commercial presses.

Packaging Heat-seal equipment, blister packaging, lidding material, and side seal belts.

Plastics & Composites Release liners for composite molding (epoxy, polyester, vinyl ester), lamination press sheets, and vacuum bagging processes.

Textile & Printing Heat press transfer sheets, curing oven conveyor belts, and drying processes.

General Industrial Gaskets, protective curtains, chemical barriers, expansion joints, and high-temperature insulation covers.