Functional Fabrics

- Model

- Functional Fabrics

Review

Description

Functional Fabrics: An In-Depth LookFunctional fabrics (also known as technical textiles or high-performance textiles) represent a segment of the textile industry defined by their integrated, non-traditional functions. Unlike conventional fabrics that primarily offer coverage and appearance, functional fabrics are developed through rigorous scientific and engineering processes to meet specific performance demands in diverse, often challenging, environments.Key Characteristics and Technologies

Engineered Performance: The defining trait is the inclusion of a function (or functions) that is quantifiable and critical to the application. This is achieved through three primary methods:

Fiber Modification: Integrating functional particles (like silver for antimicrobial properties or ceramic for thermal regulation) directly into the polymer during fiber production.

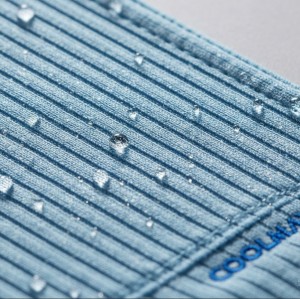

Chemical Finishing: Applying specialized chemical treatments to the fabric surface (e.g., DWR—Durable Water Repellent finishes).

Layering/Lamination: Creating multi-layer composites, such as using a microporous membrane between two fabric layers to achieve waterproof and breathable properties (e.g., Gore-Tex technology).

Multifunctionality: Modern functional fabrics often possess a combination of properties, such as a material that is both UV-protective and quick-drying.

Application-Specific Design: The fabric structure, fiber type, and finish are meticulously chosen based on the end-use (e.g., a lightweight, highly breathable fabric for a marathon runner versus a durable, flame-retardant material for a firefighter)